Smartplasma is widely used in HDI laser drilling for blind hole removal, surface treatment of hard/soft boards, removal of drilling dirt for high-thickness-to-diameter ratio high-rise boards, activation of special materials, etc. -The hole wall is etched after drilling and clearing, and the resin drilling dirt on the hole wall is removed -Remove carbides after laser drilling blind holes -Remove dry film residues when making fine lines -Activation of the surface of the hole wall of the PTFE material before copper sinking -Surface activation before lamination of the inner laminate -Surface activation before applying dry film and solder mask

The advantages of plasma treatment equipment treatment process are: -Strong controllability of processing technology -Belongs to environmental protection technology -No waste disposal cost, low processing cost -Full drying treatment -Do not use harmful substances, improve the working environment

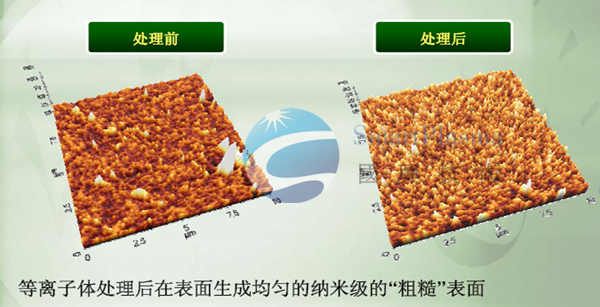

The surface of the data is selectively etched by the reactive gas plasma, and the etched data is converted into a gas phase and discharged by the vacuum pump. The processed data has an increased microscopic area and outstanding hydrophilicity. Corresponding to different materials, use the corresponding gas combination to form a strong etching gas-phase plasma and chemical reaction and physical impact with the body of the material surface, so that the solid matter on the surface of the material body is vaporized to generate gases such as CO, CO2, H2O, etc. , So as to achieve the purpose of micro-etching. Main features: uniform etching without changing the characteristics of the material matrix; it can effectively roughen the surface of the material and accurately control the amount of microetching. The plasma surface treatment machine achieves PBC removal of surface glue by plasma bombarding the surface of the object. The etching system of the smartplasma plasma cleaning machine performs decontamination and etching to take away the insulators in the drilled hole and ultimately improve the product quality. Vacuum plasma Structure: requires a vacuum system as an independent workstation Function: surface cleaning/activation, glue removal/activation in the hole, substrate etching Area of action: large area, good uniformity Capacity: General

Consult now